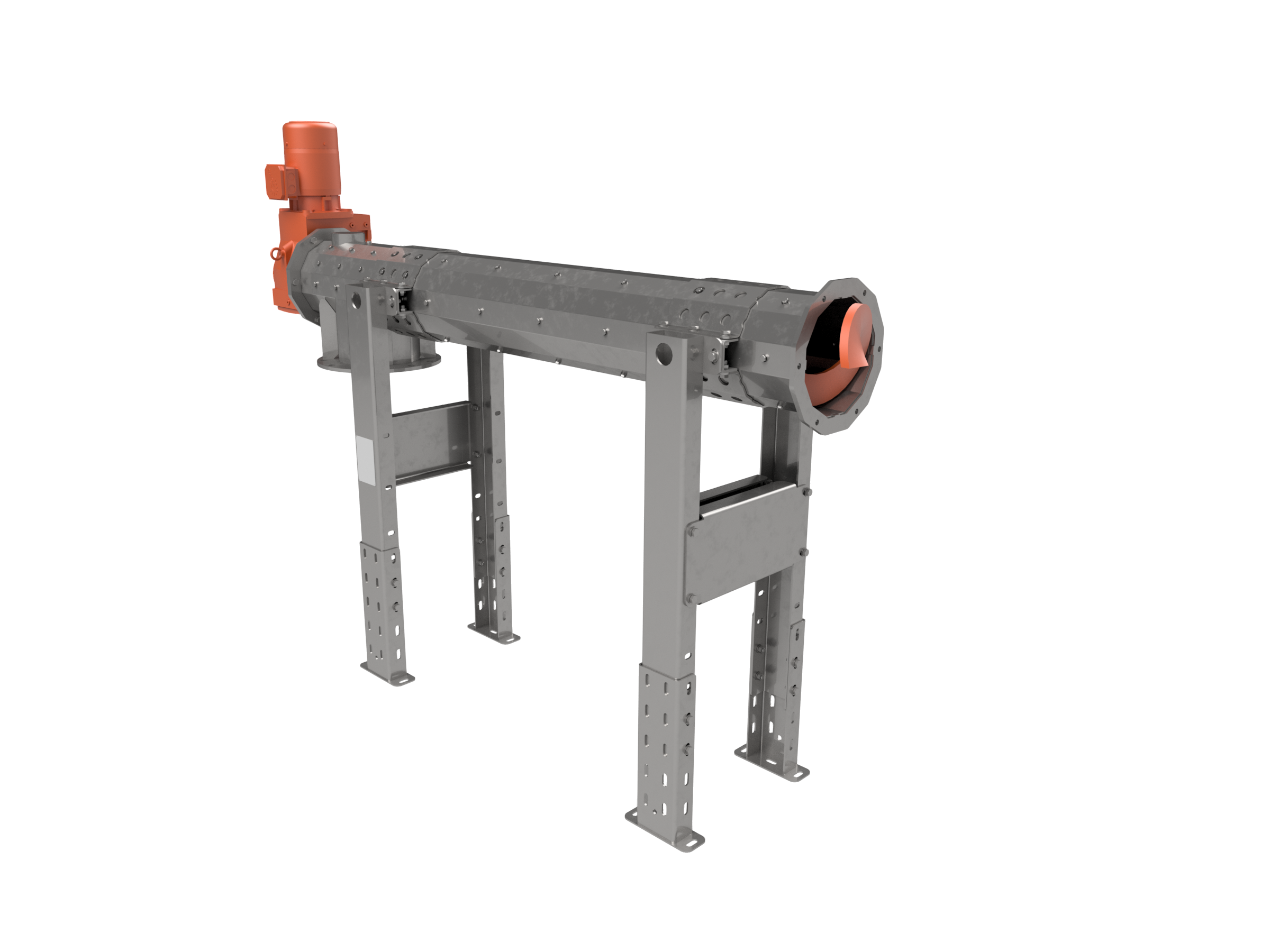

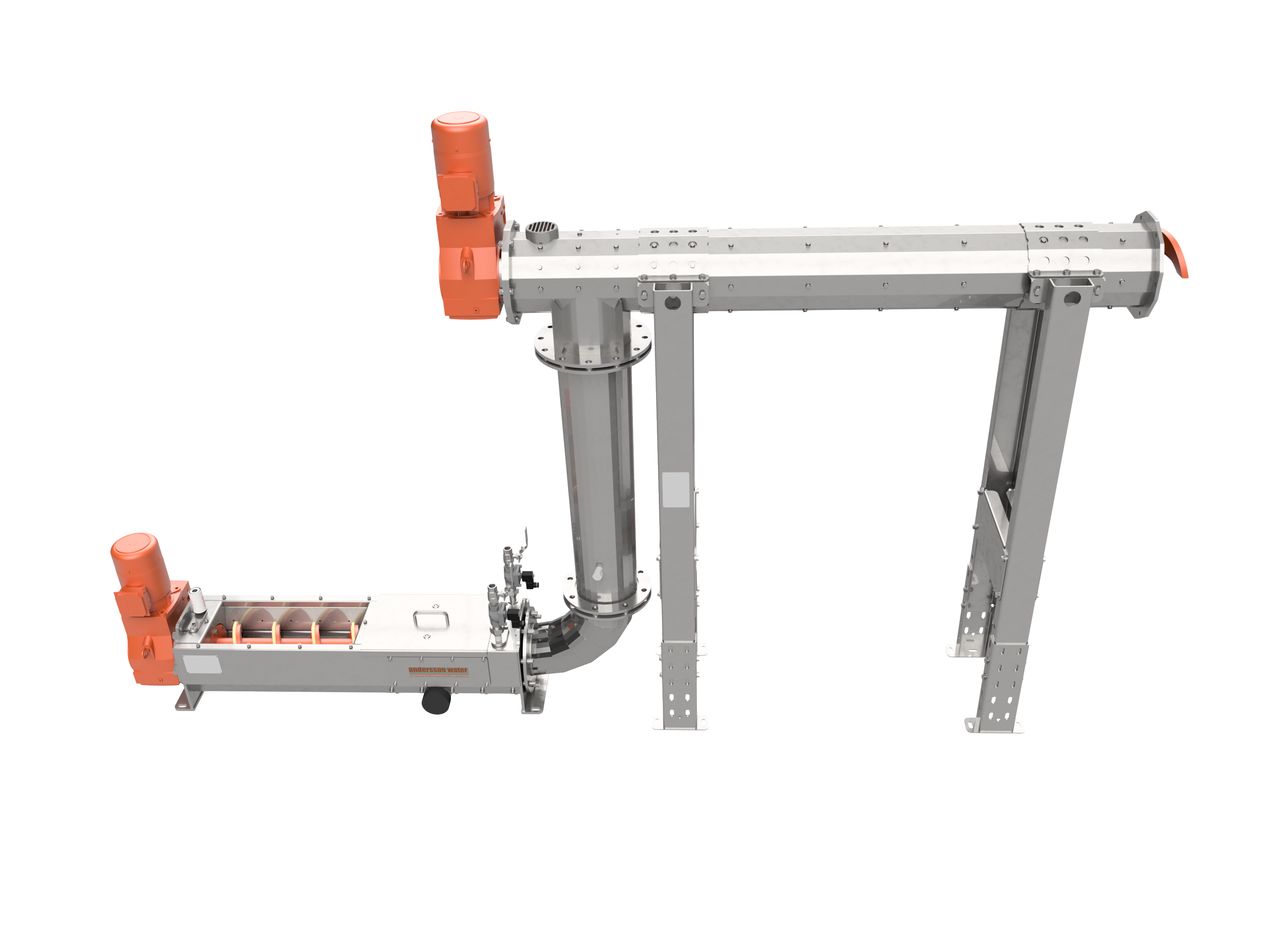

Back Pressure Shredder BPS

- Modern construction from robust certified stainless high quality materials.

- Pushing drive gives high capacity and reliable clog free operation.

- Mounted at the end of the pipe system or at the beginning gives more flexibility.

- Shredding gives good self ventilation which improves working environment.

- Eliminates need for pre wash tank systems.

- Enables emergency emptying during extreme conditions.

- Module system for easy adaptation of inlet, outlet, supports, drainage, drive unit etc.

- Enclosed, safe & hygienic with easy to open access doors.

Back Pressure Shredder BPS is an accessory for Wash Press Compactor WPC and other equipment. BPS gives maximum washing and compaction due to heavy mechanical crushing agitation and controlled retention in the compactor. This is much more efficient than impeller tank pre washing systems. BPS can be installed vertical, horisontal or angled. At the end or the beginning of a pipe system.

Specifications

- Lenght 1-50m

- Width 200-500mm

- Capacity 1-10m3/h

- Angle 0-90 degrees

- Dryness 45-55% DS

Gallery

Back Pressure Shredder BPS acts as a valve which regulates and controls the wash, dewatering and compaction retention time for Wash Press Compactor WPC. This gives max washing, dryness and weight reduction and much better results than impeller pre wash tanks. BPS shreds the material which gives self evaporation in the container which is easier to handle and fill the containers with than big lumps coming from a pipe system. BPS increases operation reliability of the compactor allowing the whole system to be emptied and cleared if blocked. This is harder to achieve with only conventional pipe systems after compactors. Pushing drive gives high capacity and prevents tangling of screenings.

Back Pressure Shredder BPS fitted after WPC to control washing, dewatering, compaction and shredding. Andersson machines are bath pickled passivated followed by bath electropolishing. The superior treatment of stainless steel

Back Pressure Shredder BPS can be mounted horisontally or vertically. BPS can be mounted at the end or the beginning of a stand pipe system.

Washed, compacted and shredded screenings >50% dryness