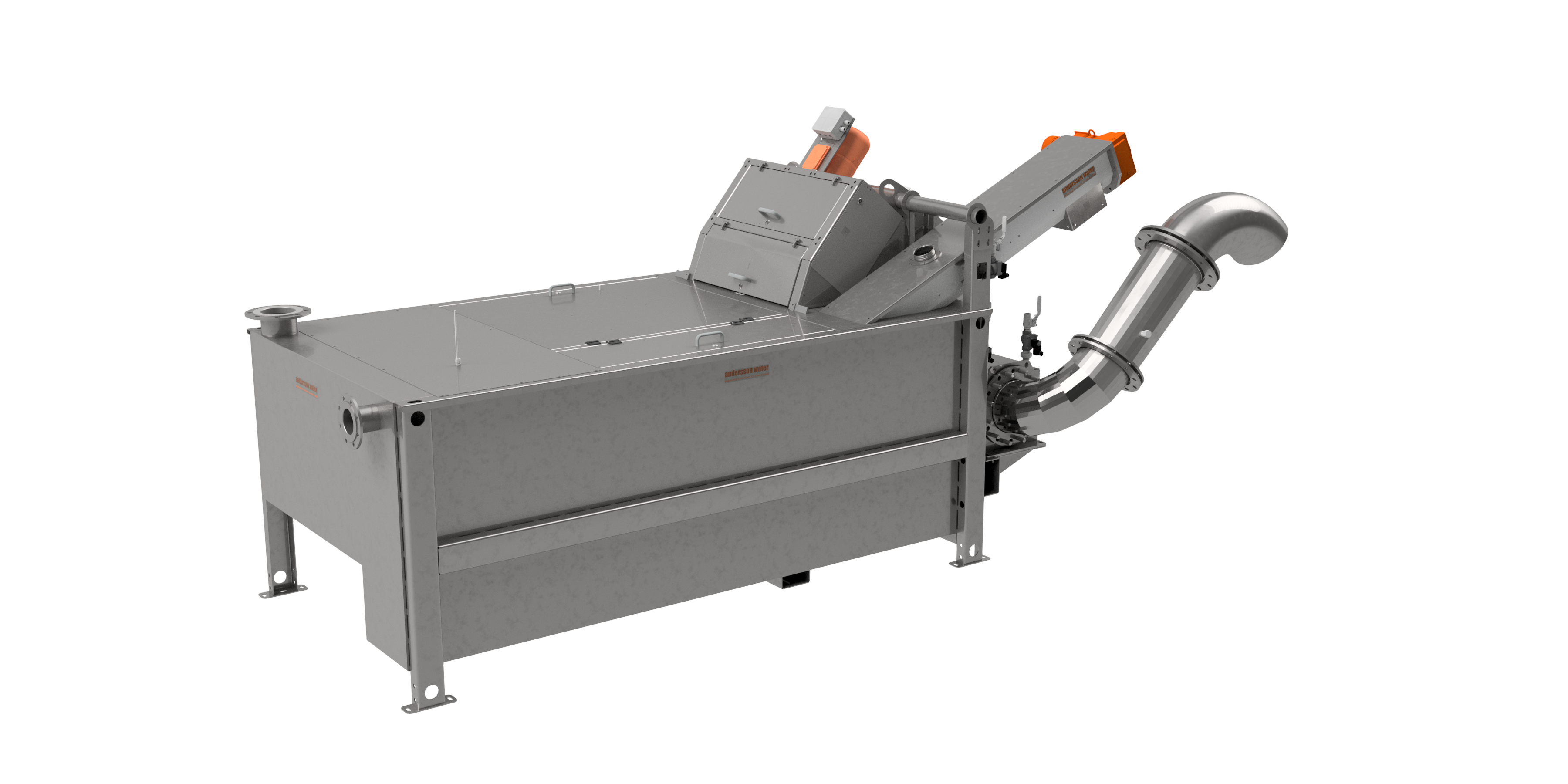

Septic Sludge Receiver SSR

– Modern construction from robust stainless high quality materials.

– Totally self cleaning. No spraying or brushes.

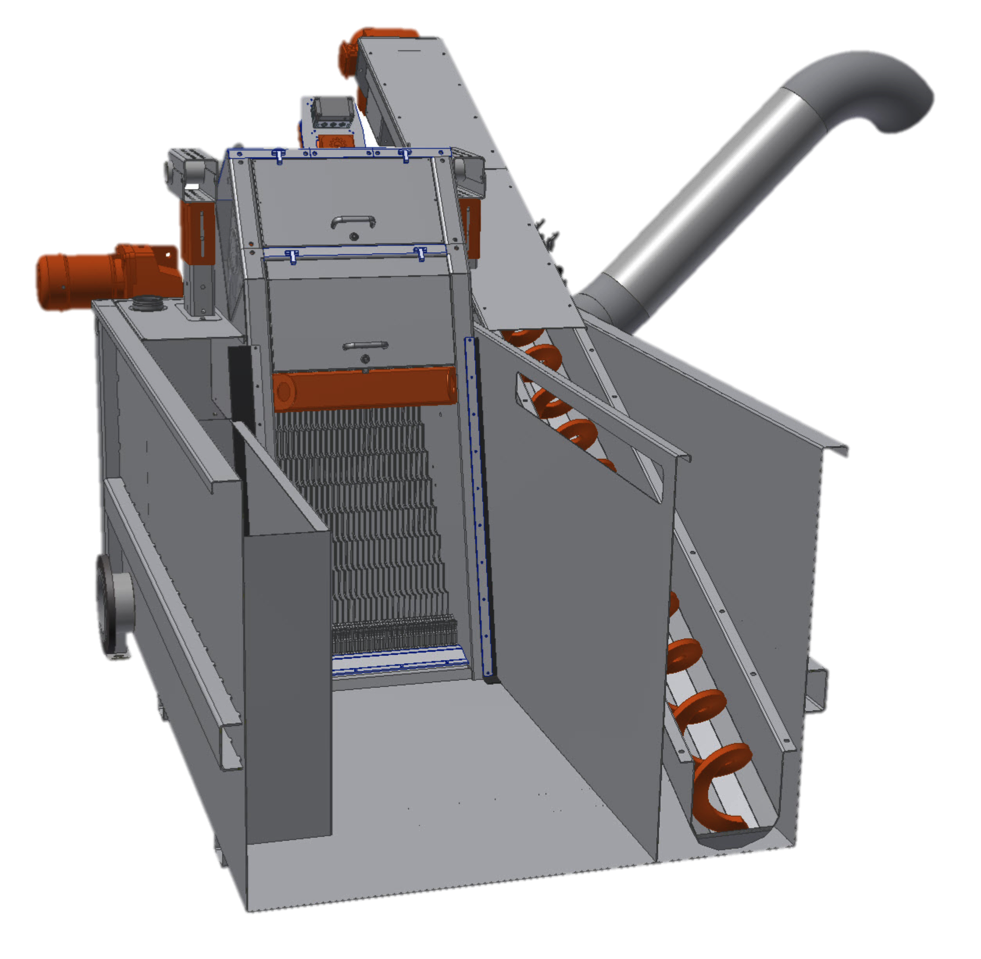

– Hinged supports enables quick pivoting out of both screen and conveyor for service.

– Enclosed, safe & hygienic with easy to open access doors.

Length 3000-4000mm

Width 1600-2200mm

Bar spacing 3-6mm

Capacity 1-6m3/min at 1-4%DS

SSR screens septic external import sludge pumped from tanker trucks or internal sludges at wwtps.

It's a non pressurised freestanding easy accessible system. Self cleaning without brushes or flushing.

SSR is fully enclosed, well ventilated with compressor tanker air evac.

It consists of a tankmounted Andersson Stair Screen ASS with 3-6mm bar spacing and

a Wash Press Compactor WPC.

SSR can be equipped with integrated stone trap compartment and stone conveyor SSC.

From the stone trap the sludge flows over a weir into the screen compartment.

The stone trap separates grit and stones to protect the screen, compactor and the

following process from wear. The separated screenings debrie is treated by the

Wash Press Compactor WPC pressing against the friction of a

stand pipe or combined with a Back Pressure Shredder BPS.

Gallery

2-4% imported and septic sludge handled on 3mm stair screen. See projects for videos

SSR is fully enclosed and handles peak load solids and compressor air from sludge truck tanker lorries with flows of approx 25-50l/s 90-180m3/h to empty 10m3 in 5min per tanker. Bigger SSR models can handle several tankers at the same time.

Integrated stone trap with spiral conveyor SSC protects the compactor from gravel and stones. Oversized compactor WPC with fully perforated brush drained inlet. Both Stair Screen and stone conveyor can easily be pivoted out for inspection and service. We have solutions for further grit separation before and after the SSR.

SSR with Stair Screen 3-6mm slot width is completely self cleaning. No flushing or brushing is required to make Stair Screen work with greasy thick material. The biggest steps on the market handles big objects and peak solid loads. Massive stainless bottom spacers gives very strong bar support and low friction for high grit handling capabilities. Stone trap with screw seen on pic right side. Emergency overflow weir seen on pic left side.

Stones are common in import septic sludge. The integrated stone trap screw separates them to protect the compactor. The stair screen is not sensitive to big stones but compactors can wear and block from it.

Stair Screen 3mm as Sludge Receiver SSR handles food industry grease and sewer sludge 1-4% from compressor tanker trucks 25-50l/s approx 90-180m3/h. Optional spray bar installed to pre wash screenings to return some screenings imbedded sludge to the process. Stair screen doesn't need any spray water

Stair Screen 3mm as Sludge Receiver SSR handles food industry grease and sewer sludge 1-4% from compressor tanker trucks 25-50l/s approx 90-180m3/h. Grit Washer Classifier GWC in background. The rattling noise is gravel going through the pipes, the SSR stone trap catches gravel effectively

Septic import sludge screenings compacted by Wash Press Compactor WPC after Sludge Receiver SSR

1pce Self cleaning Septic Sludge Receiver SSR with 3mm stair screen. Stair screen multiplies the screening capacity on greasy concentrated applications compared to perforated screens!

3mm Andersson Stair Screen ASS at headworks also functioning as septage import sludge screen. Stair Screens are totally self cleaning and excellent to screen out debrie from food waste or organic slurry before sludge digestors and or sludge dewatering.