Andersson Stair Screen ASS

- Andersson Stair Screen ASS is the worlds strongest “traditional” step screen for deep short channels.

- Several times stronger frame, bars, drive unit, transmission, bearings than others.

- Modern easy maintenance construction from robust stainless high quality materials.

- Totally self cleaning. No spraying or brushes.

- Totally self aligned bars without rakes.

- Easy replaceable strong bars and spacers.

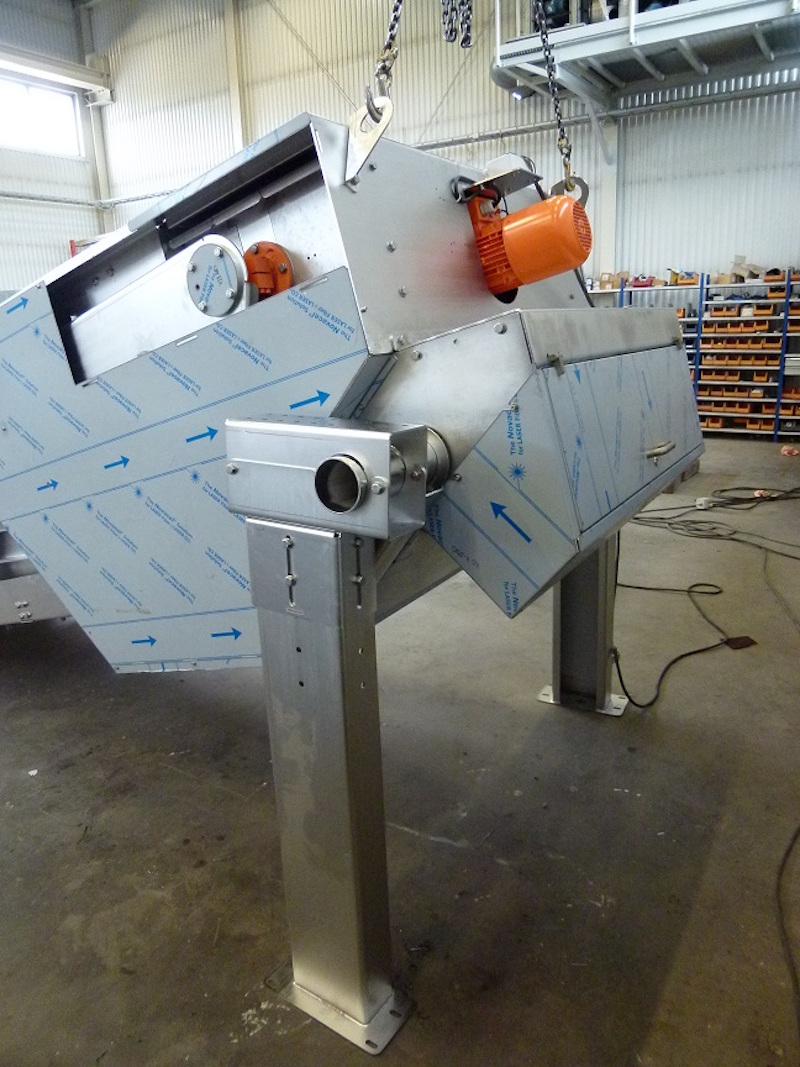

- Flexible mounting angle 45-55 degree.

- Easy adapted hinged support legs enables quick pivoting out of the channel for service.

- Enclosed, safe & hygienic with easy to open access doors.

Andersson Stair Screen ASS is a mechanical ”moving bar” fine screen that separates debrie and rubbish from water. Moving bar step type fine screens has unique capabilities: A 1-6mm Stair Screen can replace a 10-30mm coarse screen

in an existing open channel while maintaining the same low headloss, without any need for pre screening. Stair Screen ASS is totally self cleaning without flushing or brushes. This gives unrivalled capacity, result and total economy.

We recommend ASS in for WWTP headworks with short length channels. And also for channels with shallow waterlevels 800-1000mm and the channel length allows to use a 1-2mm 45 deg Progressive Stair Screen PSS we advice to do so rather than a 3mm ASS.

Specifications

- Discharge height 700-7000mm

- Width 200-2500mm

- Bar spacing 1, 2, 3, 6mm

- Capacity 10-10000l/s

Gallery

Ismo Riarbäck installation and service of all makes of step screens around the world for 35 years

Chris Ho of Aquasol Hong Kong during FAT testing at Andersson production

Stair Screen has the highest capacity and lowest maintenance of any fine screen. Stair Screen has easy to open hinged covers. Superior stainless steel surface treatment by full bath pickling passivation followed by electropolishing

Stair screen is the only 1-6mm screen that can handle 0.5-1m/s in an existing open channel designed for coarse screens. This makes stair screen the only fine screen technology that can replace any fine or coarse screen installed since >50-100 years! Fixed bar rake screens <30mm as well as perforated screens <6-10mm are often replaced by 1-6mm Stair Screens for increased efficiency and less maintenance. Stair screen is excellent as sludge screen for pre treatment of septic sludge/night soil directly from tanker trucks or for screening debrie contaminated sludge within wwtp plant processes.

Our production has since >20 years built several thousands! step screens delivered and installed over the world. The Andersson Stair Screen ASS is sprung out of that experience and is the worlds strongest step screen. Stair Screen weighs 50-100% more than any other screen technology. The constantly interleaved bar sets makes the bars support each other all the time giving a very strong and sturdy screen surface with 50-67% wet area at 3-6mm bar spacing. Even 1-2mm bar spacing is possible at headworks and greasy industries without clogging, flushing or rake misalignment issues. The stair screen gathered wear surface is huge in comparison with perforated plate screens!

Stair screens works step by step with an active pre coat layer "mat" of screenings. The step by step level and mat control gives stair screens much higher separation than other bar slot screens. Stair screens are totally self cleaning and likes grease. No brushing no flushing. Stair screens are level controlled to work intermediate step by step with an active pre coat mat of screenings. With mat a capture of up to 80% is achieved compared to up to 40% on fixed bar rake screens or slot screens with same bar spacing. This gives huge savings in maintenance in the following process. The step by step mat level control gives stair screen an effective operation time of only around 5-10% which makes stair screens very energy efficient and extremely low on mechanical maintenance compared with perforated screens and rake screens that often operate 40-80% of the time and have much more moving wear part such as chains, sprockets, brushes, scrapers, seals, panels and unhygienic flushing and spraying causing unhealthy aerosols. Perforated screens often require 50-100m3/day/each of spray water! Thats a cost of approx 20 000-40 000 euro per year! A huge operation cost and waste of resources! Independent tests has been performed on 3mm step screens with right control and screenings pre coat mat to verify their capture rate of 80% acc to international screen evaluation methods. Its important that step screens are operated with step by step level control and precoat mat. Running them on timer or crude level control will cause poor results. Unfortunately this faulty control has caused poor results on step screens in some SCR tests and is unfortunately the way many step screens around the world are operated. Step by step level precoat mat control is essential.

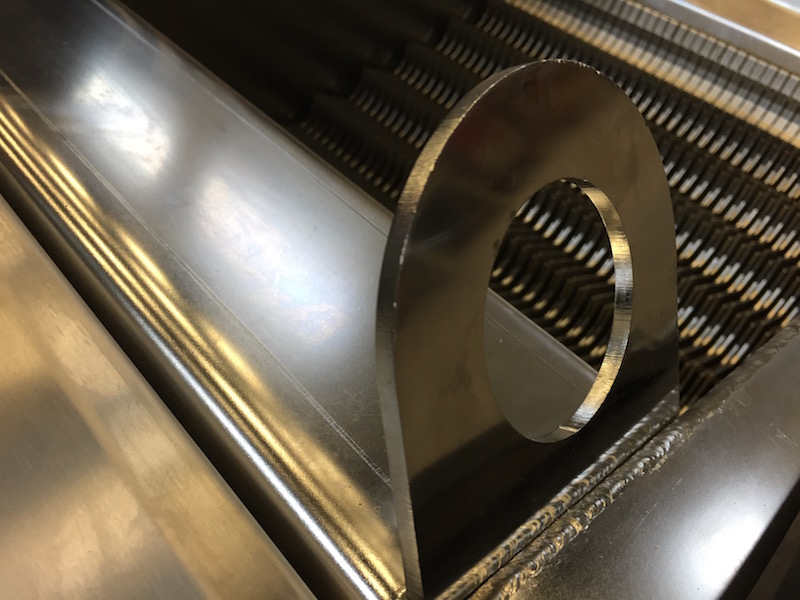

ASS has the biggest hook shape steps on the market. This increases conveying capacity and allows for 50-55 degree installations for compact footprint and high capacity. The ASS bar depth cross section is the deepest on the market which further strenghtens the bars. Both moving and fixed bars are 3mm thick. 3mm is the recommended bar thickness for step screens. Stair screen bars have more than double the cross section height/depth (approx 100mm) of conventional rake screen bars (approx 40-50mm) and many more tightly spaced self cleaned rear cross beams carrying the bars on the backside and tightly spaced bar spacers along the bars length. This together with constantly interleaved bars makes stair screen stronger than rake screens although it has thinner bars.

Low blind step with automatic bottom seal flap, strongly hinged and attached to box frame bottom beam. Massive stainless steel replaceable block spacers gives strong lower bar support guidance and low friction for high grit handling capabilities. No weak, wearing grit catching plastic spacers in the lower bottom section. Strong step screens doesn't need recessed channel steps or bottom step flushing.

ASS has the strongest highest braced box frame combined with massive rear cross beams to support the step bars. This enables the highest discharging and the widest step screens on the market. Andersson stair screens are made 2.5m wide. Other makers can't make much wider than 1.5m.

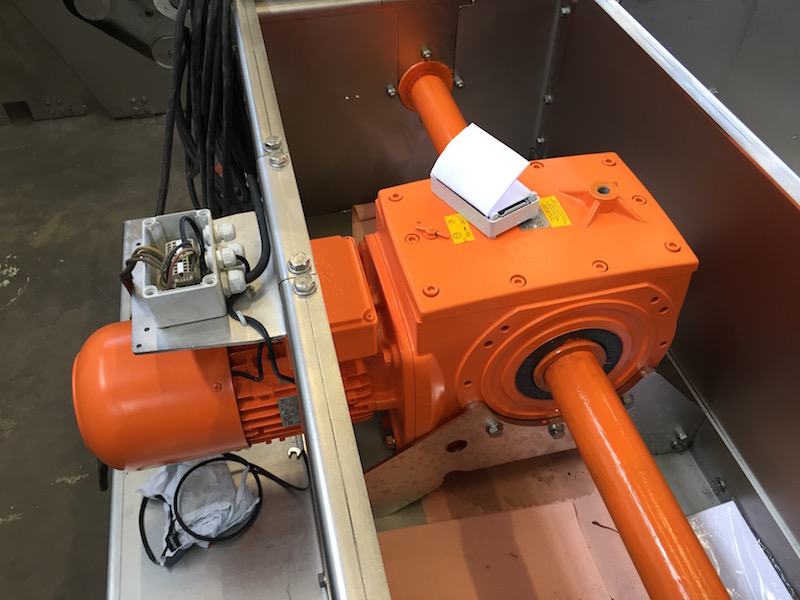

ASS has the strongest transmission with high quality efficient gearbox drive units. The whole drive unit with shaft axle and bearings can be removed easily in one piece for easy service at a workbench while the screen remains in the channel.

ASS has >60mm dia drive shaft & eccentric crank shaft ball bearing units. The ball bearings are interchangeable to optional spherical roller bearings. This is multiple times stronger than any other maker. Andersson Water small stair screen models has stronger bigger bearings than other makers use on their big step screen models!

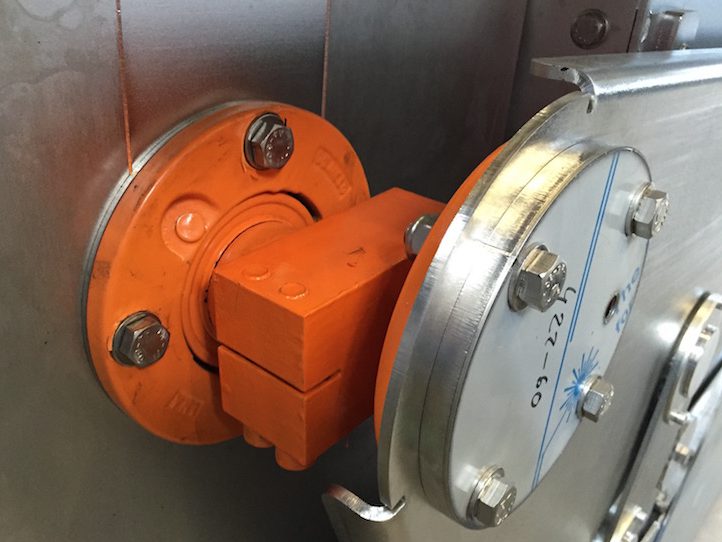

Competitors eccentric crank (left) with dia 35mm screwed crank pin seat VS Stair Screen dia 60mm massive one piece milled eccentric crank and pin

Submersible side linkage transmission with multiple >60mm dia filament wound composite bushings (used in cranes and heavy construction machinery).

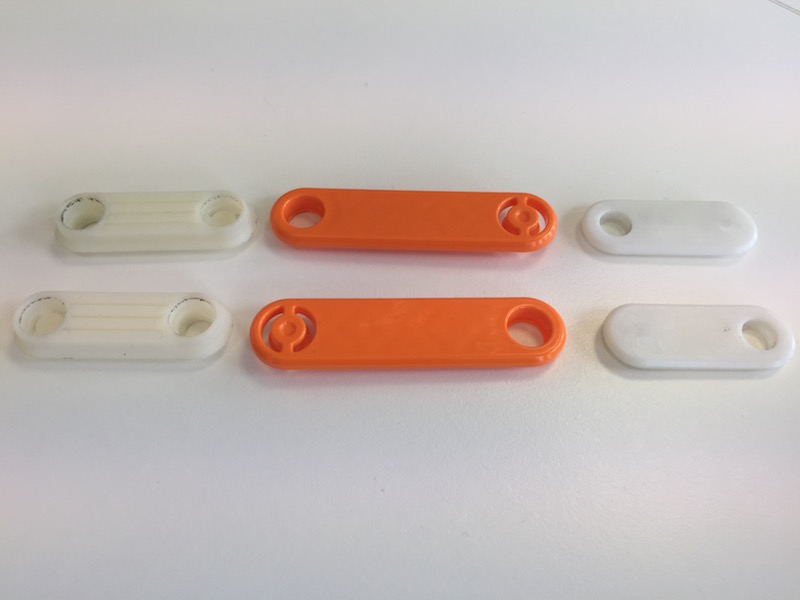

Biggest plastic bar spacer wear surface and strongest snap lock on the market ensures bar spacing and long life. (ASS orange spacers, competitors in white shown right & left for comparison)

Full bath pickled passivation followed by full bath electropolishing for optimum corrosion resistance and hygiene finish. Electropolishing gives highly increased corrosion resistance in high chloride saline sea water or extreme ph situations. We use high quality stainless steel mill certified materials preferably from Northern Europe. Our equipment is made from common alloy SS304/SS316 steels up to special alloy Super Duplex and SMO qualities with titanium fasteners.

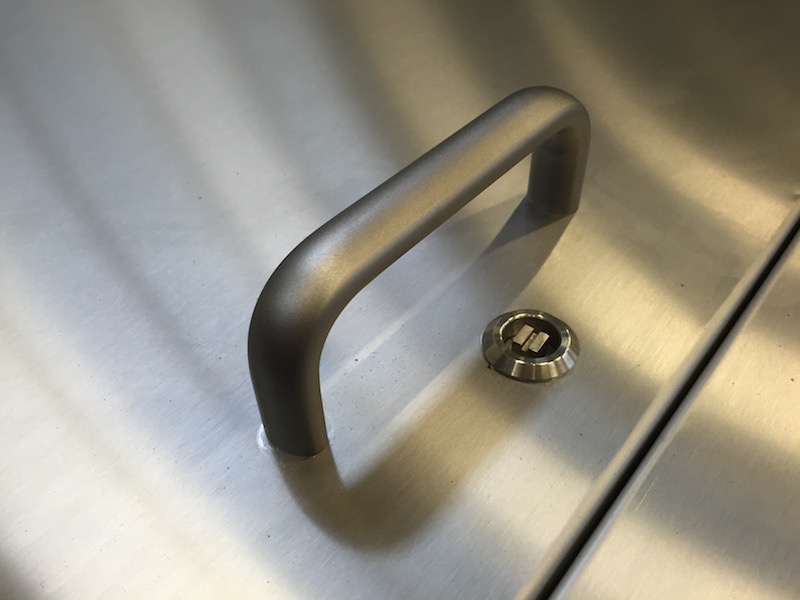

Massive high quality fully stainless steel handles, hinges, lifting lugs. Easy open hinged covers. No need for special tools, No need to lift off or unscrew/rescrew heavy hatches

Easy mounted fully enclosing rear covers. Totally enclosed for safety, hygiene and ventilation.

C profiled fully adjustable and flexible support legs allows for various mounting positions and situations.

Support legs enables easy pivot swing out of channel without dismounting the equipment behind. Easy hinged, lock & open safety covers. Covers are uniquely designed to handle blockage of following equipment without damage to the covers.

Thick 8mm reinforced rubber strips seals agains the channel walls, No grouts, no flushing or recessing into the channel bottom or walls. The markets strongest bottom sole beam and low friction bottom step. Stair Screen can easily be pivoted out of the channel by lifting at the lower adjustable lifting eye lugs. When pivoted out the channel covering is put back under the Stair Screen and service can be carried out safe and easy.

Stair Screens 1-6mm in freestanding tanks for 10-500l/s with optional compactor

Stair Screen explained at IFAT

Stair Screen explained at WWTP

Active screenings mat pre coat multiplies the capture effect and gives a 3mm stair screen 80% capture which is comparable with perforated screens. Although stair screen has much higher capacity and reliability. Stair screens of 1-2mm will work fine in any wwtp headworks channel if the hydraulics allow for it. Stair screens is totally self cleaning and do not clog even at <1mm bar spacing. In fact most of the greasiest applications are 1mm bar spacing at slaughteries, poultries, fish industry replacing 1-2mm perforated screens that cannot handle grease. Step screens like grease!

Self cleaning automatic discharge by the stepping motion. No need for scrapers, brushes or spraying. Easy open covers. Quiet, silent without splattering or unhealthy aerosols.

Stair screens can handle big objects. This machine is 3mm bar spacing and 2m effective width. Together with another 3 its installed at an Asian metropolis waste water plant headworks. Without any coarse pre screen stage needed! The gathered weight and side surface of all the bars is huge compared to rake screens or perforated plate screen which will wear out much faster. Stair screens only have one major moving part which is the moving bar set. Stair screens can handle sand, grit and gravel as good or better than any other screen technology. In the Nordic countries the winter roads are gritted and salted to enable driving and walking. Together with combined sewers this gives the highest grit loads in the world!

Stair screens high throughput area is practically without permanent clogging rate. This enables 1-3mm stair screen to stay still 90-95% of the time and work intermittent. This enables formation of the active screenings mat. Constantly interleaved self supporting bar sets with tightly spaced rear cross beams and bar spacers makes stair screen stronger than screens with thicker bars!