Raspador Plástico de Correntes KKR

- KKR is the worlds strongest plastic chain and flight scraper! Several times the strength and wear capabilites compared to others. Can replace existing chains.

- KKR has stronger transmission (shafts/bearings/drive unit) and weld sealed stainless buoyant scraper flight blades and well extended turn shafts which enables 15m wide scrapers which is more than double that of most with fibre glass flights limited to 7m with short turn shafts.

- The buoyant scraper blade flights run lightly on wheels at the tank bottom and return rails. This reduces jerking forces in the chains which further enhances life span on chains, flights and chain wheels.

- The flight support wheels can easily be changed from the tank surface without emptying the tank.

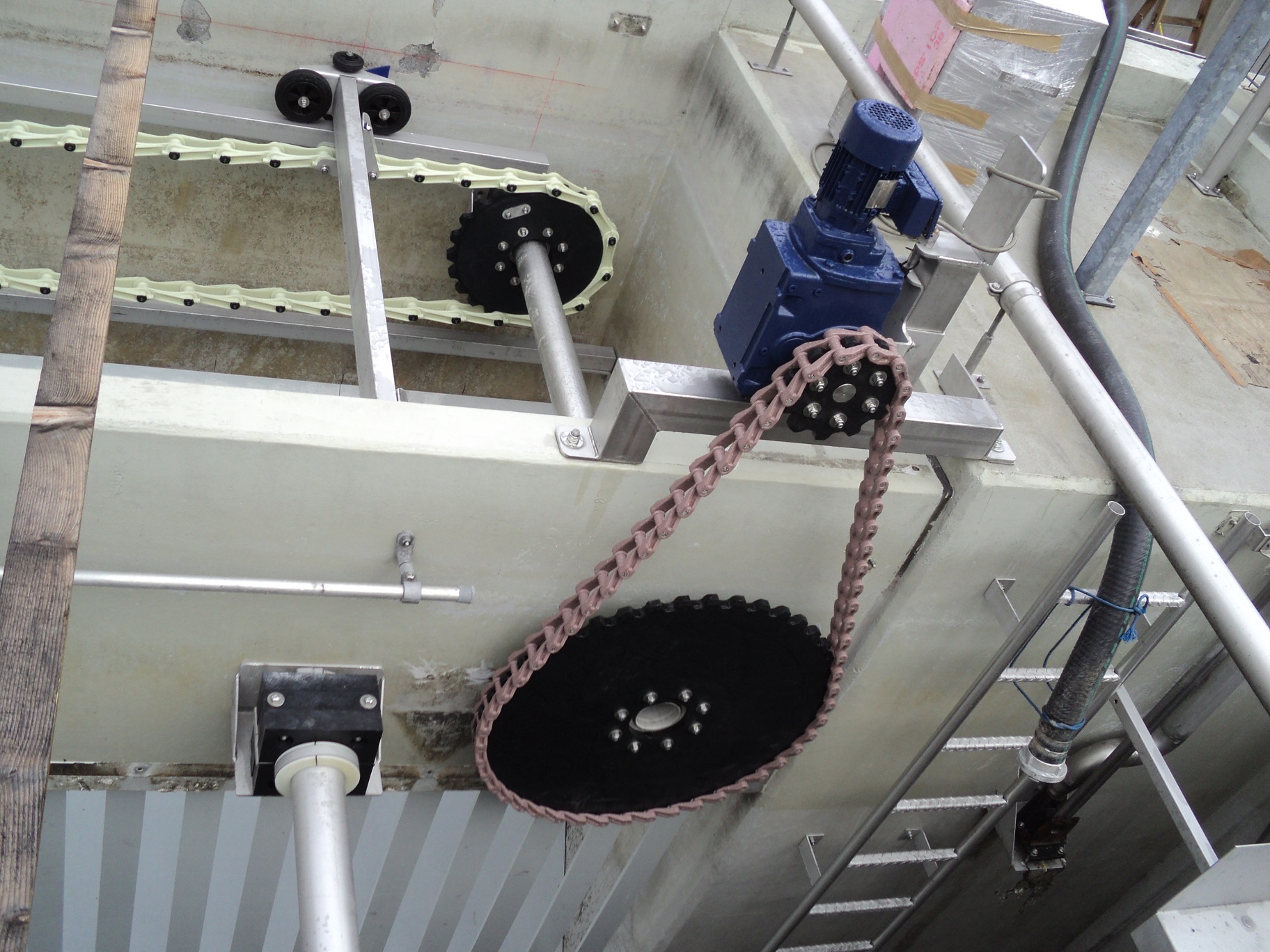

- Turn shaft chain wheels och drive shaft has easy exchangeable wear bushings clamped onto the shafts. The bushings in turn runs in split slide bearing housings. This prevents wear on the shafts.

- Patented tank surface level adapting scum screw skimmer and skimmer hopper reduces unnecessary water extraction with the scum removed.

Specifications

Length 12-120m

Width 1.2-15m

Gallery

14m wide chain scrapers is widest and strongest on the market. Competitors can rarely do more than 7m!

14m stainless buoyant back frame supported scraper flights runs light on wheels. No wear shoes on the flights. No wear strips on the tank bottom. The wheels can easily be changed from the tank surface without emptying the tank.

14m stainless buoyant back frame supported scraper flights runs light on wheels. Light running scrapers prevent jerking in the chain which makes chain, bearings, chain wheels last longer.

The KKR chain has >5.5 ton break load which is the strongest on the market compared to competitors that typically handle 2.4-3.1ton. Stainless attachment brackets connects the chain to the stainless scraper blade flights.

The attachment brackets have a flexible connection to the flights which handles 15 degree flight misalignment. Conventional fibre glass flights and fixed attachments can cause bend and twist forces which eventually weakens the flights.

The scraper blade flights are supported underneath and to the sides by wheels. Both on the bottom and at the surface on the return rails.

Chains, turn shafts and return rails are well extended out from the tank walls towards the center of the flights to enable 15m wide tank installations by better distributing the load on the flights. This increases the scraper strength significantly! Competitors have short turn shafts which weakens the scraper structure by bending and twisting the flights.

Turn shaft chain wheels and drive shaft has clamped easy exchangeable wear bushings which in turn runs in split slide bearing housings. This prevents wear on the shafts.

Rectangular grit and grease trap scraper combination. Grease scum surface scraper to the left. Grit sand bottom scraper to the right.

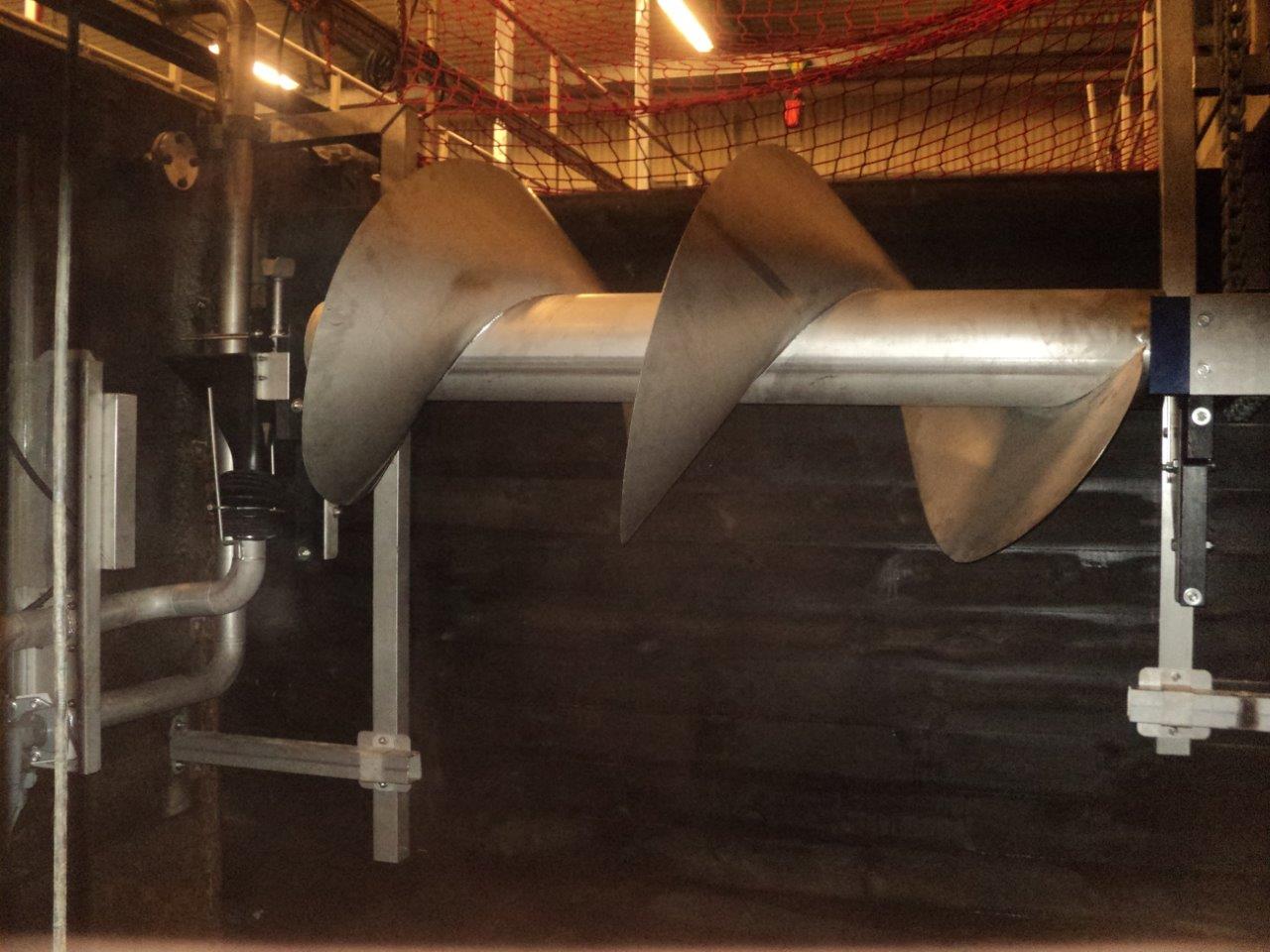

Buoyant floating screw skimmer and precision skimmer hopper follows the tank surface level variation. This reduces unnecessary water extraction with the scum from the surface.

Buoyant skimmer hopper connected to submersible pump.

Buoyant stainless screw skimmer and hopper. Buoyant stainless scraper flights on wheels.