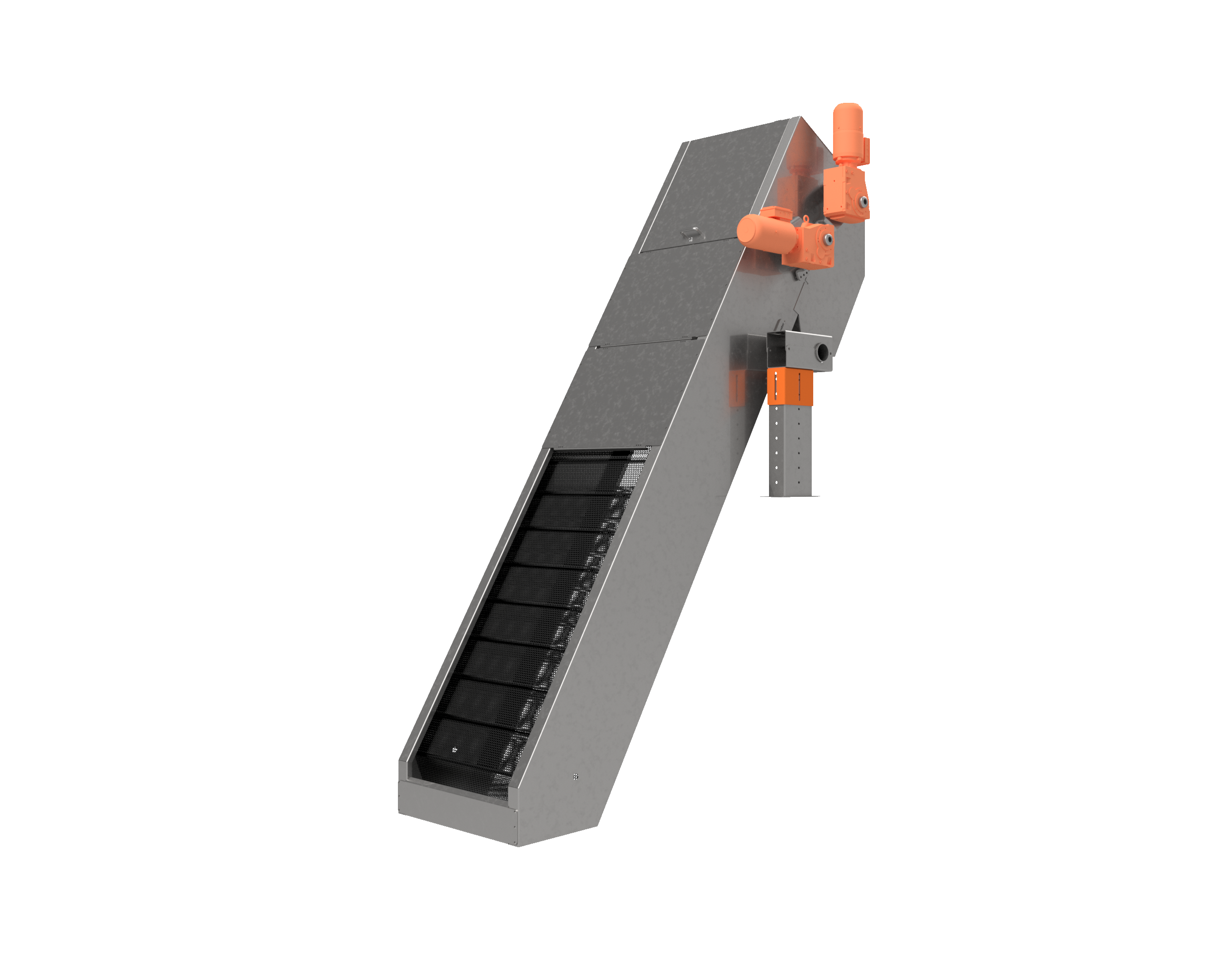

Through Flow Screen TFS

- Modern construction from robust stainless high quality materials.

- High separation in many applications.

- Stainless chains & sprockets.

- Alternative solutions for band cleaning reduces water consumption.

- Perforated plate panels or wire mesh panels.

- With or without brush to suit different applications.

- Integrated with wash press compactor, launder trough or conveyor.

- Enclosed, safe & hygienic with easy to open access doors.

Through Flow Screen TFS is the worlds strongest perforated panel bandscreen.

Through Flow Screen TFS separates solids (screenings, rubbish) from water. A band of linked perforated or mesh panels filters the water. Separated material is conveyed upwards and gets brushed/flushed off at the discharge point. The optional brush and a cleaning system keeps the perforations from clogging.

Easy replaceable screen panels with flat surface increases brush efficiency and capacity.

Efficient light brush contact reduces the need for spray water and increases panel lifetime.

Andersson Water bandscreens has the markets strongest stainless steel chains, thick split sprocket chain wheels, oversized shafts and sealed bearings all of which increases lifetime and service intervals.

Electropolished frame parts and fully covered by easy to open hinged covers. 3d adjustable pivot support legs. Cradle mounted brush

Specifications

- Discharge height 2-50m

- Width 500-3000mm

- Perforation/mesh 0.5-10mm

- Capacity 100-20000l/s

Gallery

2pcs TFS installed in compact space. Self adjusting brushes via moving drive unit on pivot axle frame

Easy open inspection covers, Easy pivot out of channel for service

Easy access hinged discharge chutes

Thick perfo panels, Rotating roller prevents screenings accumulation on the backside, Selfadjusting brush reduces brush wear and pressure causing wear to perforations and panels

2pcs TFS in freestanding tanks in compact space