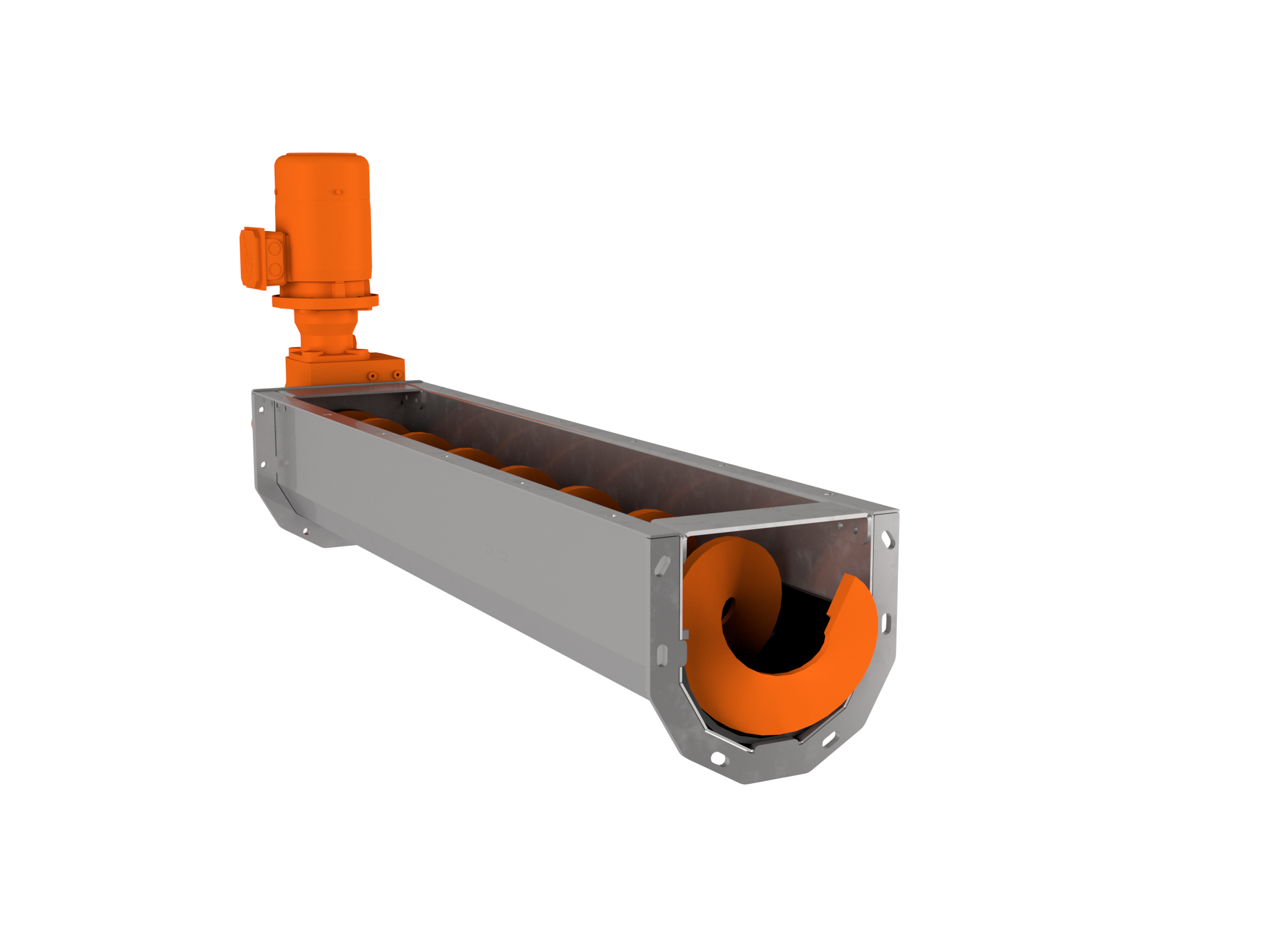

Spiral Screw Conveyor SSC

- Modern construction from robust certified stainless high quality materials.

- Our spirals are thickest on the market which enables 50m pushing drive in one piece.

- Thick easy replaceable wear surfaces in alternative materials.

- Module system for easy adaptation of inlet, outlet, supports, drainage, drive unit etc.

- Available with drainage sections and dewatering/compaction zone SSP for screenings and wet waste.

- Enclosed, safe & hygienic with easy to open access doors.

Spiral Screw Conveyor SSC conveys screenings, sludge, sand, waste. Available with drainage sections and dewatering/compaction zone SSP for screenings and wet waste. Also pipe trough conveyor design. The rotation of the spiral combined with the materials friction in the trough gives forward movement. The drive can be pushing or pulling with shaftlless spiral or shafted screw. The wear lining is low friction plastic or wear steel bars. We recommend thick spiral wound shaftless spirals whos weight and wear is distributed along the whole trough length. This is generallly better than thin flighted segment welded shafted screws which risks point wear and often requires an end supporting bearing.

Specifications

- Lenght 1-50m

- Width 200-500mm

- Capacity 1-50m3/h

- Angle 0-90 degrees

Gallery

Spiral Screw Conveyor SSC collecting screenings from 2pcs Through Flow Screens TFS

The SSC is feeding to Wash Press Compactor WPC. The SSC has bottom outlet with slide gate valve above the WPC.

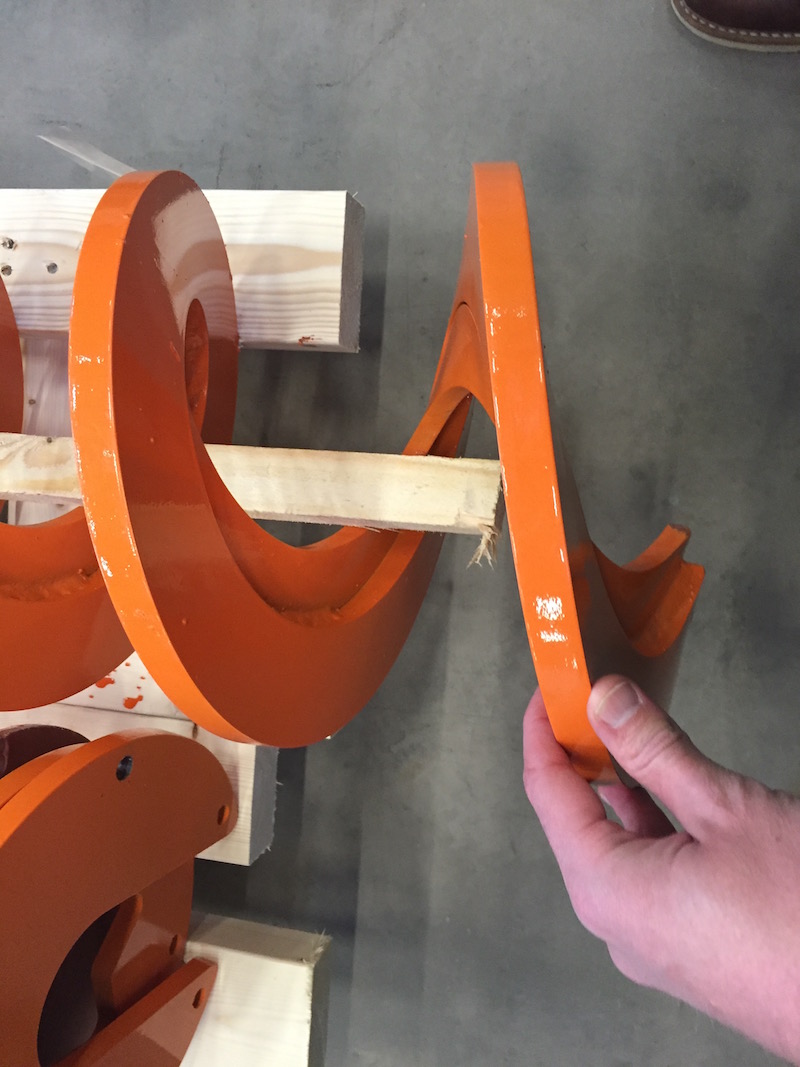

20-30mm thick flight screw spiral of wear resistant high tensile strength steel. Our spirals are used at many installations with >30-40m pushing conveying distance with one piece spirals. And also many vertical shaftless spiral conveying installations since decades. Stainless steel and shafted screws are available as lesser alternatives. Our thick flexible shaftless spirals gives superior wear capabilities and spiral weight and wear distribution over the whole conveyor length liner surface. This is more important than corrosion resistance or stiffness

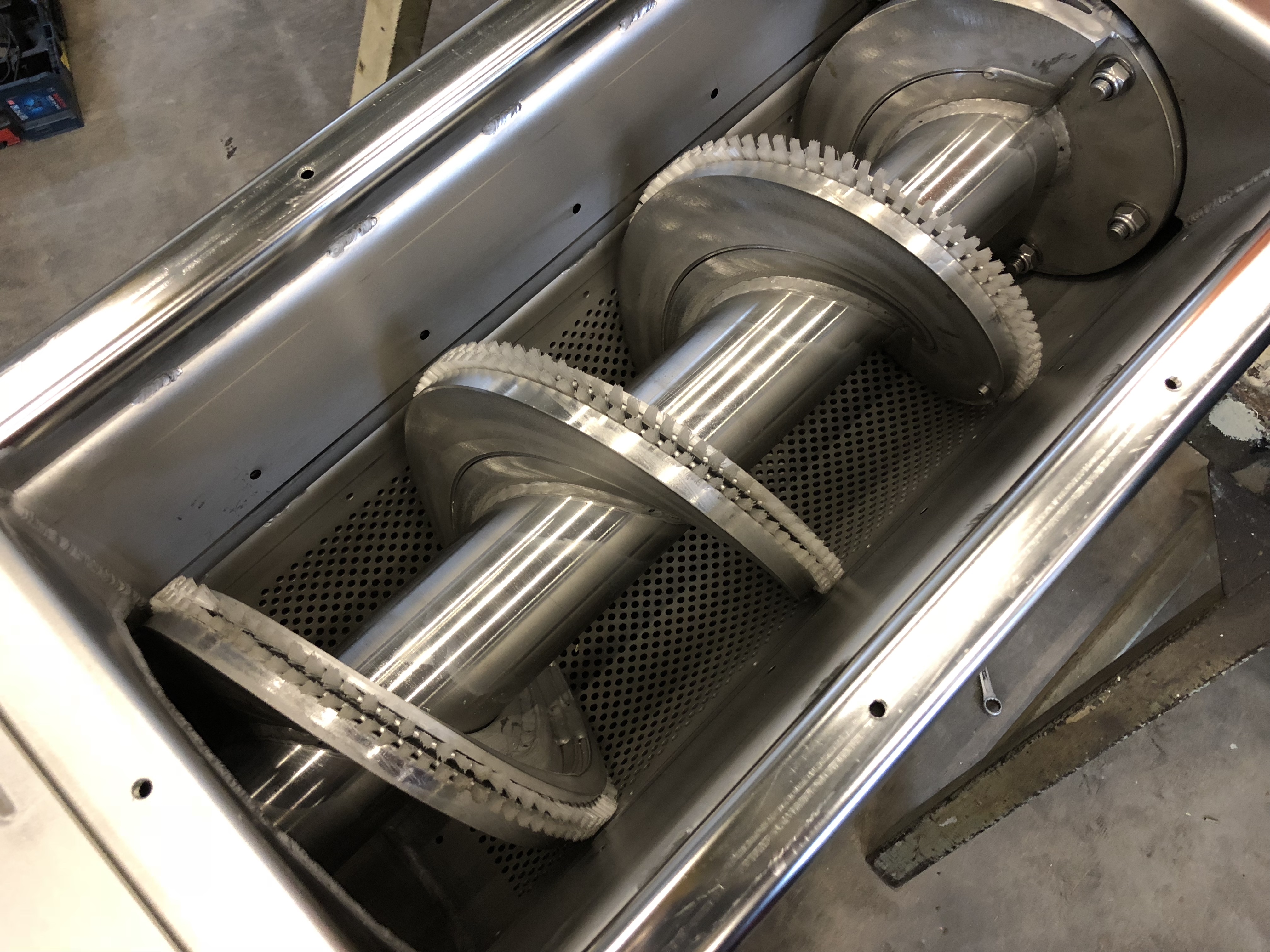

High quality oversized reinforced gearboxes with thick >50-70mm shaft transmission. Thick 10-15mm stainless steel screw trough flanges for easy service and high forces.

Wear liner low friction UHMW PE plastic or wear steel bars. Spirals 20-30mm thick with or without insert spiral

Bottom discharge slide gate valve. Enclosed and sealed with unique anti blockage design

30m pushing shaftless spiral dia 280 with cross section 60x25+25mm at a wwtp headworks. The longest pushing Andersson spiral at a wwtp application is 36m! Carbon steel spirals are stronger and more flexible than stainless or shafted screws. The advantage of shaftless spirals vs shafted screws is that a shaftless spiral flight is thicker 20-30mm compared to 10-12mm screw segments. Also, a spiral flexes so its weight is distributed over the whole conveyor length and liner. Shafted screws are stiff and need an end support bearing (which risks tangling of stringy material) or their entire weight and any slight bending causes wear points risking severe liner or trough wear.

Andersson spiral in 63m half pushing/half pulling shaftless conveyor on wood industry. Feed by vertical shaftless spiral screw conveyor. Wood gives more load, wear and friction than most wwtp sludge and screenings applications

Stainless SS316 thick wound spiral 120x25mm cross section. We rarely recommend stainless spirals due to stainless being brittle and less wear resistant than S355J construction steels.

Stainless SS316 thick wound spiral 120x25 cross section from 70x25mm main spiral + 50x25mm insert spiral. We rarely recommend stainless spirals due to stainless being brittle and less wear resistant than S355J construction steels.

Shafted SS316 wound spiral screw with 20-40mm flight thickness with welded center shaft. We mainly use shafted screws in pushing compactors. For most other applications shaftless spirals are superior due to its flexibility which gives wear distribution along the whole trough instead of just on and end bearing. Most other makers of shafted screws only use thin 6-10mm segment welded screw flights instead of thick wound 20-30mm spirals.